It’s not common knowledge or even necessarily intuitive that your sewing machine needle is a consumable. This means that even if your needle is not broken, it may still need to be replaced. It will wear out.

Let’s take a look at some of the problems that can occur with needles and need to be replaced. And how to tell if you need to swap out that needle. And some “best practices” that may work for you to keep your needles performing properly.

Reasons to Replace your Sewing Machine Needle

There are three main reasons to replace your needle, and they aren’t all simply because it’s broken so let’s first take a look at some of the reasons to change or toss the needle before we look at some of the problems caused by an inferior needle.

Damaged

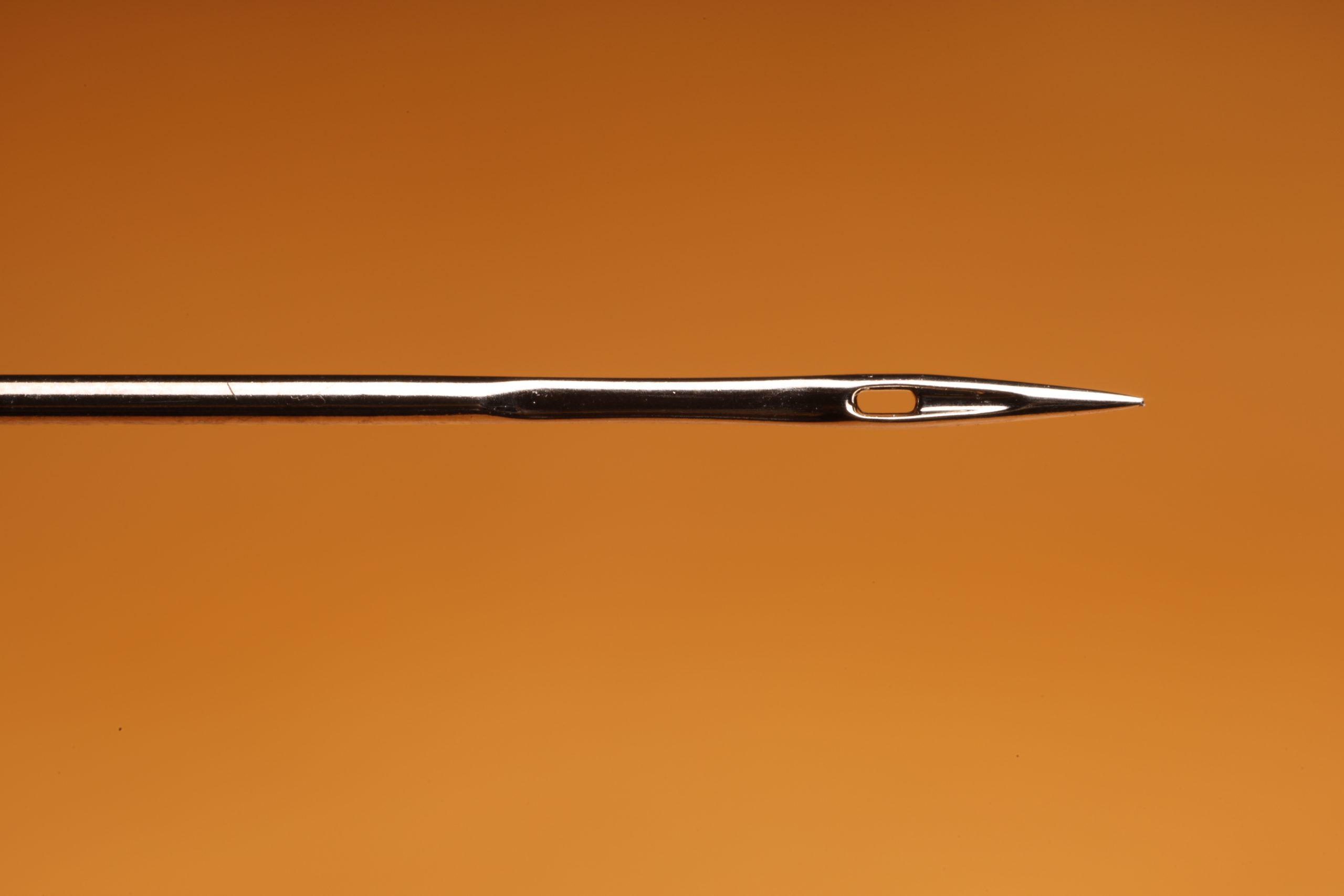

It probably seems obvious that if your needle is damaged, it will need to be replaced. Unfortunately, damage that causes problems when sewing isn’t always obvious. Especially not to the naked eye.

The most obvious types of damage are broken or bent needles.

Sometimes a needle is bent, but it’s not actually obvious, it’s just enough not straight that it won’t function properly.

You can also get nicks in the needle shaft or on the tip. And sometimes a tip will bend slightly or get a burr on it. Again, this isn’t always visible to the naked eye. But sometimes you can feel a catch on the tip of you run it on your fingernail.

And this is “damage” but not necessarily something that you can’t undo, but sometimes sticky stuff (fusibles or adhesive) can gum up your needle. If it’s not too bad, you can sometimes just clean it off with something that cleans gummy sticky stuff off metal (make sure it’s safe for your fabric). But sometimes the needle should just be tossed.

Slightly damaged sewing machine needle.

Dull

Needles will dull over time. Not necessarily time sitting around, but time being used. There are usage guidelines (hours of sewing) that I will cover in the best practices, but keep in mind that the quality of the needle, and the fabric you are sewing will affect how long the needle lasts before dulling to the point it needs to be replaced.

A dull needle might behave the same way or similar to a damaged needle, but it isn’t nearly as obvious.

Wrong

You may also need to replace your needle, or at least switch it out for a different one if it is the wrong type or size for the project you are sewing.

I have guidelines for choosing the right needle for your fabric. And some ideas on choosing a good needle size for your project.

Signs Your Needle Needs Replacing

Ok, so now you know what can “go wrong” with your needle that means you will have to replace it, let’s go over how to tell if something is going wrong, especially if it’s not obvious.

And I’m not going to lie. If you have a dull or damaged needle that isn’t obvious (like it snapped in half) it really doesn’t matter if it’s one or the other, and the symptoms can be the same.

Additionally, some of the same symptoms could just mean that you have the wrong needle. So, if you experience any of the following, you probably need a different needle.

- Popping sound while sewing

- Skipped or uneven stitches

- Fabric pulls or snags

- Thread breaking frequently

- Holes in fabric larger than normal

If you have the wrong needle, you might notice:

- Fabric damage or holes

- Thread shredding or breaking

- Irregular stitch formation

- Fabric puckering

- Machine making more sound like clunking

- Machine making more sound like it takes more power or effort to pierce through the fabric.

Obviously, some of these issues can be because of other things. For example, thread shredding could be bad thread. Thread breaking can be because of the type of winding the thread has. Or it could be too big for the needle eye (the smaller the needle, the smaller the eye of the needle). And if you have irragular stitch formation, it could be thread tension settings. And if you have fabric puckering it could be stitch settings.

But some of those things are harder to dial in so if you replace the needle with a brand new needle, and try a size up or down or a slightly different type, and the problem doesn’t go away, you should look at some of these other settings. So often, though, it’s the needle. And that’s a pretty simple fix.

It should go without saying but I’m going to say it anyway: Small problems as listed above, will become bigger issues if not addressed. You could have serious machine jamming or you can damage your fabric beyond what can easily be hidden. So don’t ignore these early warning signs of “bad” needles.

Best Practices

Ok, so what are some things you can do to prevent issues caused by needing to replace the needle?

Well, You can try to keep track of how many hours each needle has on it. If you only sew with one type of fabric primarily so you only have one size and type of needle to keep track of, this would be easier. But if you, like me, sew a range of fabrics and frequently swap needles to accommodate your projects it gets much more difficult.

You could also try just swapping out a needle every time you finish a major project. But this could cause you to sew too long on one and you’ll still have issues. Or you could sew too short on one which costs more in needles. Though, sometimes the cost of needles is less than the cost of the problems caused by a bad needle.

My go to “best practice” is:

When in doubt swap it out.

Sometimes I just swap out a needle if I think I’ve used it for a while or I can’t remember when I started using it.

If I start experiencing any of the above issues, I almost always just swap the needle first. Well, not true, I will check stitch setting (just to make sure I told the machine to do what I think I told the machine to do). And I will often also check the threading of the machine, at least visually to make sure something really weird didn’t happen. But my go to for fixing issues is changing the needle.

Swap your needle out to a brand new needle. And if it doesn’t fix the issue, try a different type or size, or type and size.

Is there needle maintenance that you should do?

Not really. Sure, if you have a tiny burr on the tip of your needle you might be able to fix it with the little strawberry on the side of your tomato pin cushion. That little strawberry has abrasive granules in it that is supposedly used to sharpen pins and needles. And it kinda works. But it won’t work on big burrs or nicks.

If you sew fusibles like fusible interfacing or fusible web, or if you sew through self-adhesive velcro, or tape, then clean your needle before it gets gummy. You can also try using a silicone lubricant (like sewer’s aid) on it to ward off the gumminess. And there are needles out there that theoretically resist the stickiness of these kinds of things but I haven’t tested them.

So, yeah, when in doubt swap it out.

Conclusions

To summarize, many issues are caused by dull, damaged or incorrect needles. If ignored, these smaller issues can become big problems and ruin your project.

Needles are consumables and they need to be replaced. Get in the mindset of replacing them for better quality results and far fewer frustrations.